History

FEI-Elcom Tech, Inc. was founded in 1995 as a design and manufacturing company specializing in various DRO’s (Dielectric Resonance Oscillators) based RF frequency sources. We are experts in RF hardware design, digital design, embedded software, PCB design, mechanical design, schematic layout, and systems software including graphical user interfaces. Our product designs combine MIC, MMIC, Hybrid Thin, and Thick Film technologies with the aid of the latest CAD tools, simulation software and test equipment.

Today, FEI-Elcom Tech builds High Performance Ultra-wideband Electronic Warfare Solutions :

- Electronic Attack (EA), Electronic Countermeasures (ECM), Electronic Counter Counter Measures (ECCM)

- Combat Electromagnetic Environment Simulator (CEESIM) for F35, F22, F18, F16 and B52

- EW and Radar System Calibration and Test

- Deployed Built in Test & System Calibration

- Advanced Electromagnetic Spectrum Analysis

- Receivers for SIGINT, COMINT, ELINT

Past Performance :

FEI-Elcom Tech signal generation and conversion products are deployed around the world in airborne, seaborne and rugged terrestrial environments. In flight synthesizer, converter and receiver installations serve UAV, rotary wing and fixed wing missions in the United States, and abroad.

They are deployed in seaborne combat control centers, EW Automatic Test Equipment (ATE) and C3ISR systems by the US and foreign navies. Rugged terrestrial environments include all weather flight line EW ATE systems, arctic based SATCOM and ELINT ground stations as well as desert unmanned COMINT listening posts.

Customers include US DoD, and primes including BAE, Northrop Grumman, Lockheed Martin, Boeing, Agilent Technologies, L3 Communications, General Dynamics, NAVAIR, Rockwell Collins, Raytheon, and Comtech EF Data.

FEI-Elcom Tech has delivered 1000’s of EW solutions which perform beyond the reach of our competitors. Our ability to meet or exceed the most challenging customer requirements is the reason why we are the “go-to” company when defense and communication companies require exceptional designs for tough requirements.

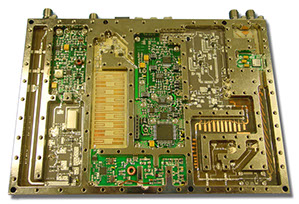

Electronic Warfare Modules :

Our products are used in the most sophisticated EW solutions. We provide

- Synthesizers – Ultra low phase noise, Ultra fast switching phase coherent and phase continuous,

- RF Front Ends- Ultra low phase noise, 2-40GHz Ultra Wideband, Very large IBW – 1GHz,

- Up/Down Converters, Ultra low phase noise, 2-40GHz Ultra Wideband, Very large IBW – 1GHz, and

- Receivers, Lowest SFDR for any commercially available ADCs, Multiple channels.

FEI-Elcom Tech delivers the best performing EW RF modules available. Our key product differentiators are:

- Ultra low phase noise

- Ultra fast phase coherent switching synthesizers

- Ultra fast phase continuous switching synthesizers

- 0.5 – 67 GHz Ultra Wideband Frequency options

- Very large IBW up to 1GHz options

- Lowest SFDR for any commercially available RX’r

- COTS and custom products in VPX and VME options

- DOD MOSA and SOSA aligned options

FEI-Elcom Tech has a global customer base including industry leaders in both the aerospace defense and commercial markets. Besides providing solutions to defense departments and defense ministries around the democratic world, FEI-Elcom Tech, Inc. has enjoyed continued growth in its customer base including BAE, Northrop Grumman, Lockheed Martin, Boeing, Agilent Technologies, L3 Communications, General Dynamics, NAVAIR, Rockwell Collins, Raytheon, and Comtech EF Data.

Specialization

Elcom designs and delivers RF Modules operating at frequencies up to 67 GHz. We provide fast switching speed, low phase noise (jitter), and ultra-wideband solutions for Electronic Warfare, Radar, Electromagnetic Environment Simulator, SIGINT, and emerging 5G wireless applications. Our design approach is based on a combination of MW circuit design and FPGA based proprietary DSP.

Elcom products include T/R modules, Up / Down Converters, Synthesized Signal Generators, Block Converters, Switchable Filter Banks, and Phase Locked DROs. We offer COTS and custom products in VPX and VME open system based on the DOD Modular System Approach (MOSA). Also, we offer stand-alone ruggedized and hermetically sealed modules.

The company offers COTS and custom products in VPX and VME open system based on the DOD Modular System Approach (MOSA). Also offered are stand-alone ruggedized and hermetically sealed modules.

Engineering is Our Passion

Elcom has a team of highly experienced engineers from multiple disciplines including MW and RF hardware design, digital design, embedded software, PCB design, ME design, schematic layout, and systems software.

The performance of any RF chain or RF subsystem is dependent on multiple design considerations of the many building blocks that are joined together at the module and system level. When customers require maximum RF performance in their application, we are their partner of choice. Our engineering team reflects a critical mass of technical core competencies unmatched in the industry. They include:

- PLL Algorithms and Topologies

- High-Frequency Filter Design

- Low Phase Noise Oscillators

- Fast Switching Synthesizers

- RF Digital Signal Processing

- Compressed Form Factors

- Reduced Footprints

- Low Power Consumption

- FPGA Design and Embedded Software

- System-level software and GUI

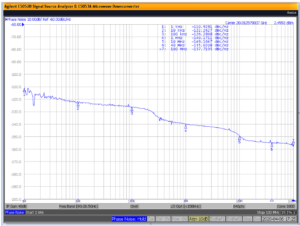

Engineering Design and Test Environment

Elcom has invested in the infrastructure necessary to test, debug and produce solutions for our customers and we have invested in training on the most up-to-date manufacturing and assembly processes. This includes:

- Agilent ADS and Genesys RF EDA

- OrCAD PCB Design

- Pro Engineer 3D CAD

- MATLAB

- AutoCAD

- LPFK ProtoLaser 100 Laser System

- HALT HASS Test Chamber

To facilitate tuning and testing, each station is equipped with Spectrum Analyzer 9 KHz to 26 GHz signal source, Scalar Analyzer, scope, temperature plates (hot and cold) and microwave power meter. Test stations are computer-controlled with application-specific software developed to make typical measurements. Elcom produces highly sophisticated microwave subsystems for major programs, some having production runs as long as 15+ years.

- MMIC Dry Storage

- RF & MW Module Assembly

- LabView ATE

- Testing Capability up to 40 GHZ

- RF Cable Assembly

- Hermetically Sealed Packaging

- Wire Bond Testing

- 100% Burn In

- MICRON Geometries (GaAs)

- Chip: Wire Hybrids

- Thin Film Circuits

Quality Assurance – Commitment to Quality

We are committed to providing our customers with the highest quality products possible. FEI-Elcom Tech, Inc.’s QA Department is involved in all stages of the product lifecycle, from product design specification, through product development, testing, production, and product revisions. All of our design, procurement, manufacturing, test, inspection, and general business processes are documented, measured, controlled, and continuously improved per ISO 9001:2015. The keystone of our corporate quality strategy is to cultivate a work environment where all of our employees understand that quality, reliability, and customer satisfaction should be the focus of all our day-to-day activities.

Elcom’s Quality Policy

FEI-Elcom Tech, Inc. is committed to achieving customer

satisfaction providing quality products through

- Accountability

- Continuous Improvement

- Teamwork

The Elcom Quality Policy requires that each Elcom employee embrace the principles in the acronym ACT described above. Each Elcom employee is Accountable, must Continually strive to Improve product and processes, and Team with fellow employees and customers to achieve customer satisfaction.

Inspection and Test Processes

New product development requires complete design verification to customer specifications before release to production. This design verification cycle typically includes HALT (Highly Accelerated Life Testing) to determine if product margins and reliability are sufficient prior to production release.

As a supplier to Department of Defense Agencies, Prime Defense contractors and worldwide (US Allied) defense organizations, Elcom has implemented many processes based on AS9102 including First Article Inspection and Foreign Object and Debris (FOD) prevention and detection.

All products are 100% functionally tested and inspected during the production process including ESS (Environmental Stress Screening) or HASS (Highly Accelerated Stress Screening).

Quality Assurance performs a final product performance audit before products are shipped to the customers.

Elcom Customers may require Design Reviews, on-site source inspection, a government source, First Article Acceptance Testing, Pre-cap inspection, etc. Elcom welcomes this interaction with its customers as it builds both confidence and teamwork and ultimately improves the understanding of critical customer requirements and Elcom capabilities.

Certifications

FEI-Elcom Tech’s quality programs have been audited and certified to comply with ISO-9001:2015 since 2018.

Workmanship, Inspection and Test Standards:

IPC-A-610E, Class 2 and 3, Standards

FEI-Elcom manufactures RF systems and sub-systems to IPC-A-610E, Class 2 and 3, Standards. All Elcom assemblers and QA Inspectors are certified to IPC-A-610E and receive annual training in required skills. Elcom QA has a Certified IPC Trainer (CIT) on staff to allow for easy training and recertification as needed.

Assemblers are NASA 8739.2 certified and a NASA level B instructor (IPC-A-610 CIT) is

also on site.

MIL-HDBK-454, MIL-STD-202, MIL-STD-461, MIL-STD-810, RTCA/DO-160

Elcom manufactures products for the defense sector conforming to MIL-HDBK-454 which are tested or inspected to standards such as MIL-STD-202, MIL-STD-461, MIL-STD-810 and RTCA/DO-160 (Safety of Flight) among others.

Warranties

The standard warranty on FEI-Elcom Tech products is 12 months. If a product fails during the warranty period, it will be repaired free of charge. Extended warranties are available with an additional charge.

After the initial standard 12-month manufacturer warranty period expires, repairs made will be charged on a time and material basis. For most products, an initial evaluation fee will be charged to assess the unit, and the customer will be advised regarding repair costs prior to the work being performed. Please see the detailed RMA procedure below.

Please refer to the RMA CUSTOMER PROCEDURE for guidelines on returning materials for repair. Read more in our RMA Customer Procedure. A Returned Material Authorization (RMA) number can be obtained by first submitting an RMA AUTHORIZATION FORM to customerservice@fei-elcomtech.com Prior to shipment a RETURN TICKET must be completed and attached to the box. Should you have any questions, feel free to call the Customer Service department at 201-767-8030.

CAGE: 1UWV0

UEI: RDXKF1E5XJE3

SOCIO-ECONOMIC: Small Business, Publicly Traded (NASDAQ:FEIM), Small Traditional Defense Contractor

NAICS 334511 – Warfare countermeasures equipment manufacturing

NAICS 334515 – Instrument Manufacturing for Measuring and Testing Electricity and Electrical Signals

NAICS 541715 Electronic research and development laboratories or services (except nanotechnology research and development)

PSC 5963 – Electronic Modules